+86 13989613556

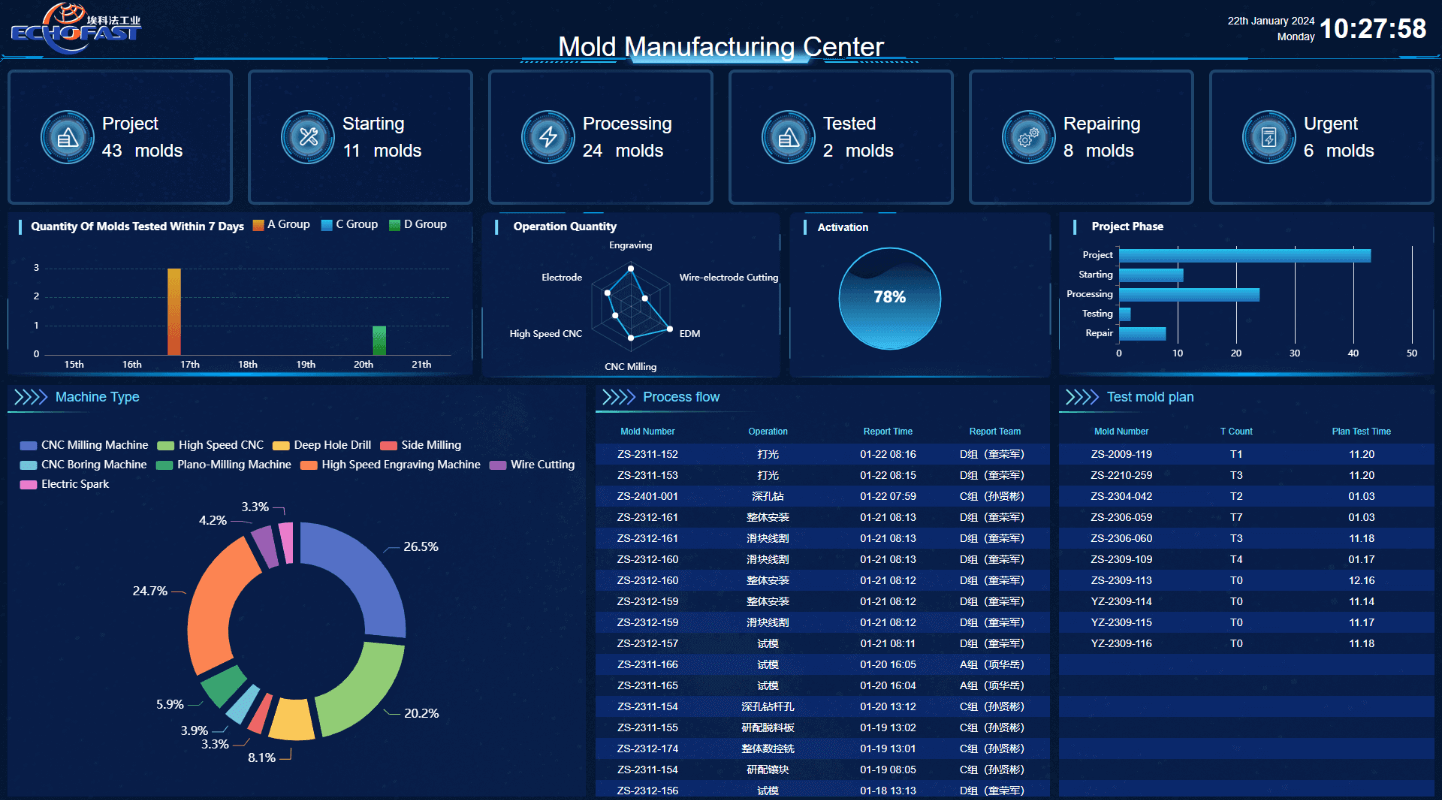

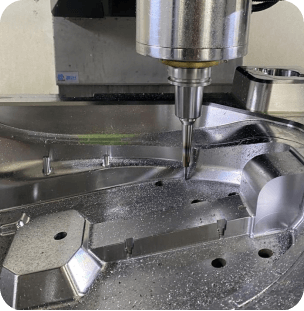

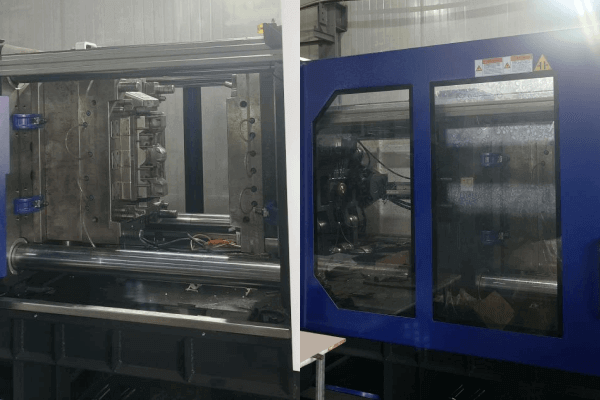

Echofast serves the quick-turnover, plastic injection molding

industry.

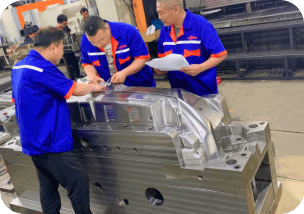

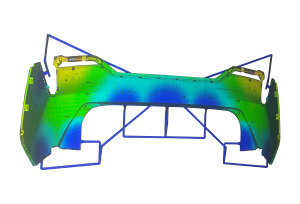

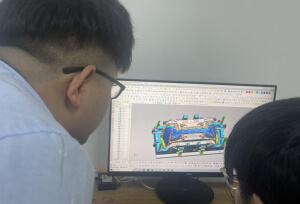

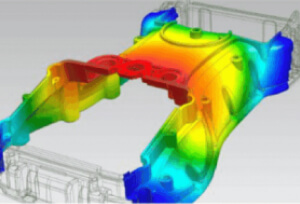

We have mold design and manufacturing,injection

molding, precision machining core technology, as well as the

industry's advanced testing equipment.With the advancement of

in-house technologies, we now offer the core injection molding

service,which guarantees that we do it all from prototyping to

parts through production.

Some factors should be taken into consideration:

| Service | Details |

|---|---|

| Lead Time |

About 30 days, but the specific time is mainly based on the mold structure |

| Production Options | Domestic and international |

| Materials |

Most plastics, including custom sourcing and matching; see materials list below |

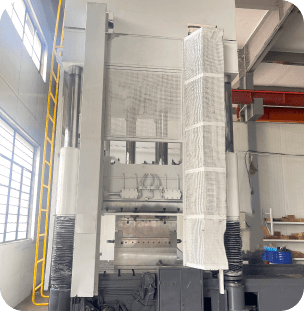

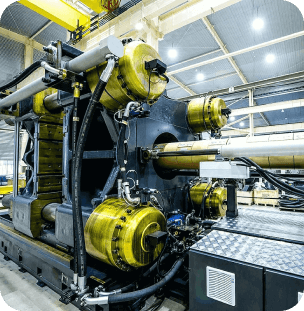

| Machines Available |

Single, multi-cavity, and family molds; 50 to 2,500+ injection molding tonnage; side actions including hand-loaded cores. |

| Inspection and Certification Options | ISO 9001: 2015 |

| Tool Ownership | Customer-owned with mold maintenance |

| Mold Cavity Tolerances |

+/- 0.005" when machining the mold and an additional +/- 0.002" per inch when calculating for shrink rate |

| Critical Feature Tolerances |

Tighter tolerances can be requested and may increase the cost of tooling because of additional sampling and grooming. |

| Available Mold Types |

Steel and aluminum; Production grades range from Class 105, a prototype mold, to Class 101, an extremely high production mold. |

We can offer you more than 100 thermoplastic materials.

Thermoplastics

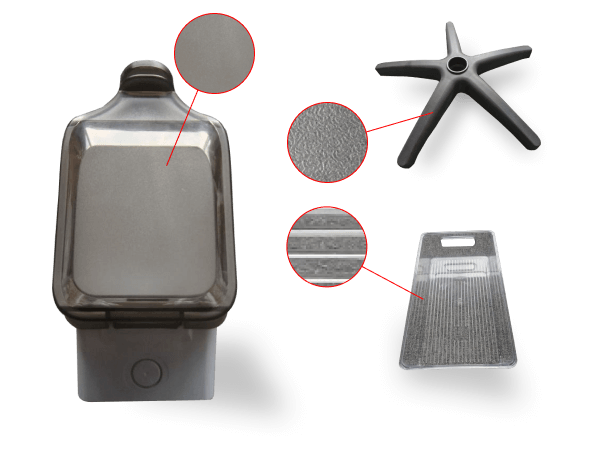

Draft angle requirements will vary by requested finish.Industry standard Mold-Tech finishes are also available.

| FINISH | DESCRIPTION |

| PM-F0 | non-cosmetic, finish to Echofast’s discretion |

| PM-F1 | low-cosmetic, most toolmarks removed |

| PM-F2 | non-cosmetic, EDM permissible |

| SPI-C1 | 600 grit stone, 10-12 Ra |

| PM-T1 | SPI-C1 + light bead blast |

| PM-T2 | SPI-C1 + medium bead blast |

| SPI-B1 | 600 grit paper, 2-3 Ra |

| SPI-A2 | grade #2 diamond buff, 1-2 Ra |

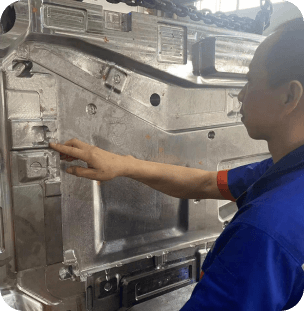

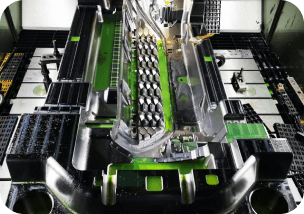

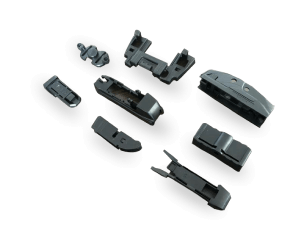

Plastic injection molding is ideal for producing high volumes of the same object.

To help you find your ideal injection molding, we offer you the catalogue of injection mold.

You can download it whenever you need.

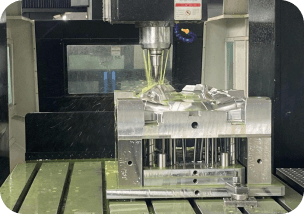

Good Quality

Globally Competitive Pricing

We are located in Huangyan Mold Processing Cluster in Taizhou , Zhejiang province ,China, which

is the largest mold processing cluster in the world.Professional division of labor and abundant technical

engineer resources are available for better control in our company. We are aimed to maintain a sustainable cost

advantage for customers with custom plastic injection molding .

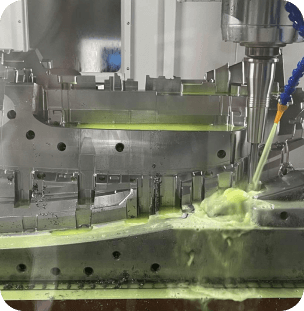

Please contact us now! Get a professional custom plastic injection molding quote within 24 hours.We

provide expert engineering reviews for you.Dozens of materials and finishes are available.We

provide you with a professional quotation list.

Catalogue

Catalogue