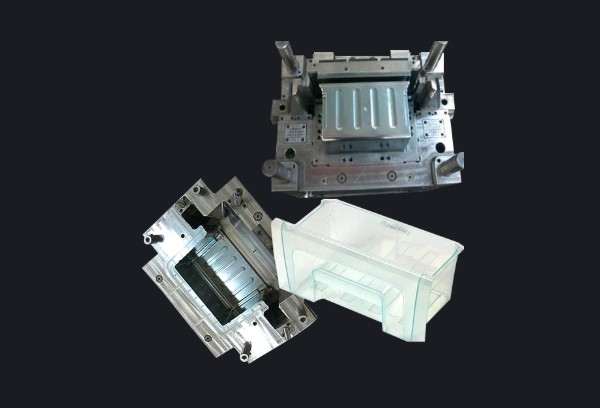

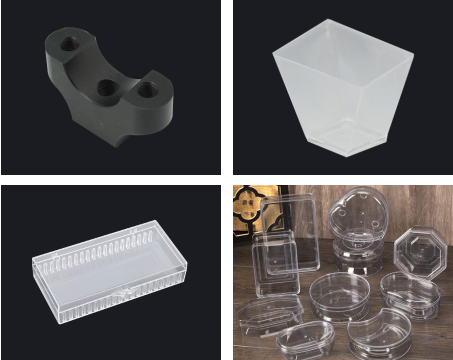

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. It can be solid or foamed.It is a light weight material popular for its high impact strength and toughness. Polystyrene (PS) injection molding is a manufacturing process for producing parts by injecting molten Polystyrene (PS) into a mold. Echofast offers custom plastic mold service with expert consultation on each injection mold quote, and we can meet your unique needs while providing a fast and easy manufacturing experience.

| Wall thickness | Between 0.76 and 5.1 mm. |

| Ribs & stiffeners | 60% to 50% of the supported wall’s thickness |

| Radii | Depends on the type of polystyrene |

| Draft angle | Between 0.5 and 1% |

| Part tolerances | Either commercial or fine |

|

Unreinforced PS |

Impact Modified PS |

Transparent PS |

Heat Resistant PS |

||

|---|---|---|---|---|---|

| Physical | Density (g/cm3) | 0.857 | 1.05 | 1.04 | 1.05 |

| Linear Mold Shrinkage Rate (cm/cm) | 0.00509 | 0.0060 | 0.00539 | 0.00557 | |

| Rockwell Hardness (R) | 100 | 94.8 | 121 | 105 | |

| Mechanical | Tensile Strength at Yield (MPa) | 43.7 | 25.9 | 43.6 | 45.9 |

| Elongation at break (%) | 25.8 | 44.8 | 3.14 | 9.74 | |

| Flexural Modulus (GPa) | 3.47 | 2.14 | 3.11 | 2.99 | |

| Flexural Yield Strength (MPa) | 69.2 | 54 | 76.2 | 82 | |

| Injection Molding | Drying Temperature (°C) | 92.2 | 78 | 76.7 | 76.2 |

| Melt Temperature (°C) | 250 | 216 | 220 | 215 | |

| Mold Temperature (°C) | 69.5 | 49.6 | 52 | 52.9 |

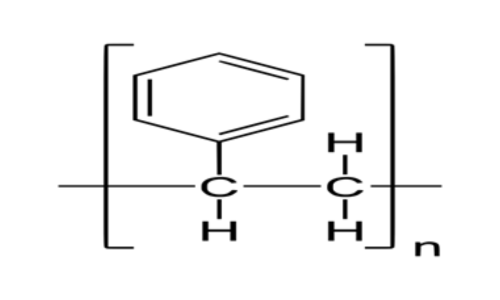

| Chemical Formula | (C8H8)n |

| Melting Point (°C) | ~215°C |

| Melt Temperature | 210-249 °C (410-480 °F) |

| Typical Injection Molding Temperature | 38 – 66 °C (100 – 150 °F) |

| Heat Deflection Temperature (HDT) | At 0.46 MPa (66 PSI), HDT is 95 °C (284 °F) |