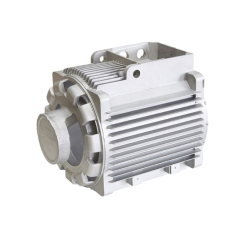

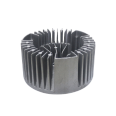

Common Materials Used in Die Casting for Motor Housings

The motor housing needs to have high strength, good heat dissipation,

and excellent electromagnetic shielding. Therefore, aluminum is

usually used in the die casting process as the material of the motor

housing.

ADC6

ADC6 is an excellent material for motor housings. It is a low-copper,

high-silicon die-cast alloy with excellent castability and certain

mechanical properties. The main components of ADC6 are aluminum,

silicon and sodium. Due to its low copper content, ADC6 is not prone

to defects such as pores.It is ideal for products such as motor

casings that require high strength and high castability.

ADC12

ADC12 is a die-cast aluminum with high strength, corrosion resistance

and good machinability.

Its main components are aluminum, copper, indium and platinum. It is

widely used in motors for its excellent mechanical strength and

corrosion resistance. However, due to the high copper content,

castings are prone to defects such as pores and thermal cracks, and

high-pressure shooting technology is required for casting.

ADC5

ADC5 is a high-performance, high-strength, high-temperature die-cast

aluminum. The main components of ADC5 are aluminum, zinc and platinum.

Because of its excellent high-temperature performance and strength, it

is widely used in high-load fields such as motors and engines.

However, due to the high zinc content, castings are prone to defects

such as shrinkage cavities and pores, requiring strict preheating and

temperature control measures.