FAQ

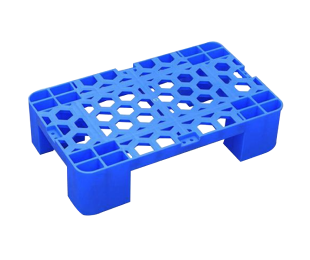

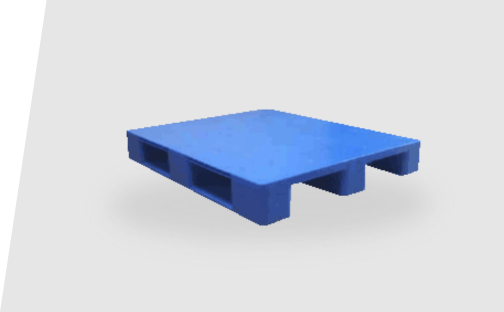

1.What is the weight capacity of plastic pallets?

Plastic pallets of different sizes and styles have different

load-bearing capacities. Generally, the dynamic load of light plastic

pallets is between 0.5 tons and 1 ton, the dynamic load of

conventional pallets is between 1 to 1.5 tons, and the dynamic load of

built-in steel pipes is about 1.5 to 2 tons. The manufacturing

material has a greater impact on the load-bearing capacity of a

plastic pallet.

2.Is it better to use HDPE or PP as the raw material for injection

molded trash cans?

The raw material of injection molded trash cans is generally HDPE or

PP, and the specific choice depends on the use and requirements of the

trash can. Relatively speaking, HDPE is more commonly used to make

trash cans because it has better flexibility, corrosion resistance,

and is environmentally friendly. At the same time, trash cans made of

polyethylene are easy to clean and will not age or deform after

long-term use. Trash cans made of PP are more suitable for some

specific occasions, such as medical institutions, food industry,

laboratories and other places that require good corrosion resistance

and high temperature resistance.

3.Are injection molded turnover boxes toxic?

No, they aren’t. They are non-toxic and non-polluting due to the

characteristics of their raw materials. They are easy to dispose of

after use and will not cause pollution to the environment. The waste

can also be reused and made into other plastic products.