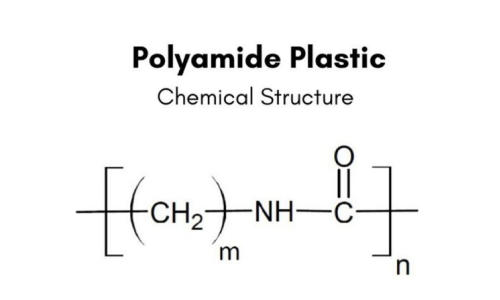

Nylon is an engineering thermoplastic and commonly used injection molding material that is a polyamide (PA). Nylon injection molding is a process that is used to form injection molded nylon products. It relies on heating and injecting the nylon plastic into a mold. Echofast Injection Molding processes nylon through standard injection molding procedures, forming molds with attractive properties.

There are something worth considering in the design of Nylon Injection Molding :

Drying

Drying , especially vacuum drying, is necessary for Nylon. It is a crucial step before Nylon can be melted and molded, because excess water will degrade the plastic when it’s exposed to heat.

Clamping

The two pieces of the mold are clamped together in the process of clamping, which is before injection. Both sides are put into a clamping unit, which is a machine that pushes them together.

Injection

The injection itself begins after clamping. Feed Nylon pellets into a hopper. After that, the plastic is melted down to liquid form and pumped into the mold.Make sure that the temperature is kept constant throughout the procedure.

Dwelling

The mold is filled with the liquid in the dwelling phase. Pressure is applied in order to keep the structural integrity of the part by letting the liquid fill all the mold cavities.

Cooling

Following the injection, we enter the cooling stage. The plastic solidifies inside the mold, which can take from seconds to minutes according to the part size.

Ejection

The mold is opened and the part is ejected from the mold to reveal the final nylon plastic product.

| Nylon 11 | Nylon 12 | Nylon 46 | Nylon 66 | Nylon 6630% GF | ||

|---|---|---|---|---|---|---|

| Physical | Density (g/cm3) | 1.04 | 1.31 | 1.20 | 1.17 | 1.38 |

| Linear Mold Shrinkage Rate (cm/cm) |

0.0083 | 0.00694 | 0.0190 | 0.0139 | 0.00440 | |

| Rockwell Hardness (R) |

107 | 98 | 95 | 114 | 117 | |

| Mechanical | Tensile Strength at Yield (MPa) |

37.1 | 46.1 | 73.9 | 72.5 | 155 |

| Elongation at break (%) |

119 | 67.4 | 43.4 | 47.1 | 4.03 | |

| Flexural Modulus (GPa) |

0.948 | 5.66 | 2.64 | 3.09 | 7.96 | |

| Flexural Yield Strength (MPa) |

119 | 136 | 108 | 229 | ||

| Nylon Injection Molding |

Drying Temperature (°C) |

90 | 92.6 | 93.7 | 81 | 82.2 |

| Melt Temperature (°C) |

261 | 224 | 303 | 279 | 285 | |

| Mold Temperature (°C) |

48.9 | 70.7 | 103 | 74.9 | 86.1 |

Nylon plastic (PA) , with wear resistance and chemical resistance, is a durable and versatile material. It is often used as a more affordable and convenient alternative material to products requiring high strength, durability, and outstanding chemical and thermal properties. Material Advantages of nylon include:

High melting temperature

Compared with other engineering plastics, Nylon plastic (PA) has a higher maximum operating temperature. It has a higher melt temperature and even greater high-temperature resistance. It will not degrade when overheated again – it will melt back down when cooled off, making it reusable.

Low friction

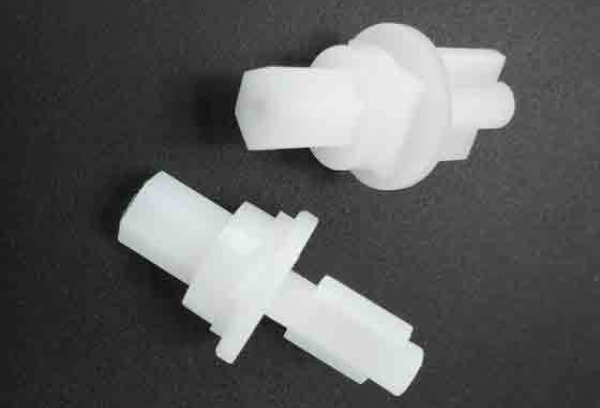

Nylon possesses a low coefficient of friction with high wear resistance. Its smooth surface means that the material is self-lubricating, so there is no need for lubricant.Therefore, it is a favorable material choice in movable mechanical parts.

High tensile strength

The specific tensile strength of Nylon is higher than metal whereas the compressive strength of Nylon is comparable to metal.

Resistance to chemicals and abrasions

This material is corrosion-resistant. It is also highly resistant to alkali, weak acids, oil, gasoline, aromatic hydrocarbons, and general solvents, which makes it have the outstanding endurance and anti-aging ability. As a result, it can be used as packaging material for lubricants and fuels.

Gassing

Excess gas can cause such defects as shorts/unfill, poor/chalky appearance and inadequte filling in of rib/detail areas.Gassing can be avoided by setting the mold at the right temperature and allowing vents to help escape the gas during the molding process.

Moisture

Nylon is the most hygroscopic and can quickly take in moisture among all materials.Poor drying can cause gassing and other potential scrap-producing defects. It is essential that the resins are dried well before processing for Nylon injection molding.

Shrinkage

Nylon is one material that is more prone to shrinkage.Nylon shrinkage can result in reduced strength, poor color, and warped edges, but it can be avoided by controlling the heat and molding temperatures.

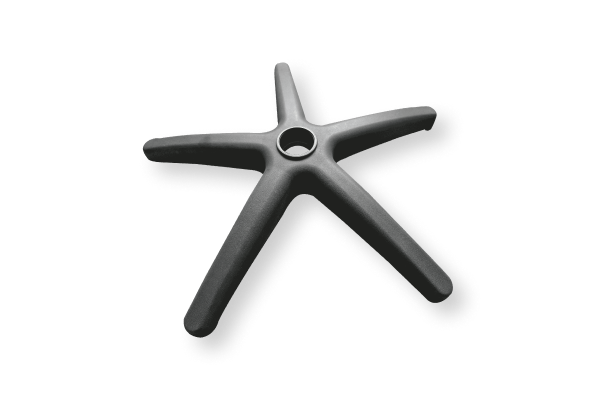

Because of its high-temperature strength, wear resistance and

chemical resistance, Nylon is used in many industries such as

automotive, aerospace, military, chemical processing, construction

and medical supplies.

Some applications: