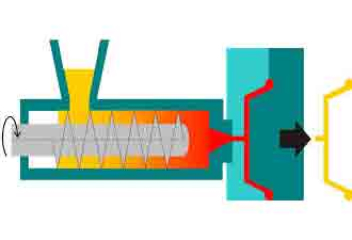

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer with a semi-crystalline structure. It is used predominantly in injection molding applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene injection molding refers to the process of heating a thermoplastic polymer above its melting point and converting it into a solid polymer and a molten fluid. Then, this molten polypropylene is injected into the mold and the desired shape of the part can be obtained. You can have splendid PP injection molding services in Echofast.

| Properties | Polypropylene |

|---|---|

| Density (g/cm3) | 0.9 |

| Ultimate Tensile Strength (MPa) | 23.4 |

| Izod Impact (Notched) (J/cm) | 4.27 |

| Hardness (Shore D) | 72 |

| Max Service Temperature (Air) (°C) | 82.2 |

| Melting Temperature (°C) | 160 - 168 |

| UV Resistance | Poor |

| Chemical/ Corrosion Resistance |

Resistant to diluted and concentrated acids like nitric acid, as well as alcohols and bases |

| Water Absorption (ASTM D570) (% by weight) | 0.02 |

PP injection molding features a variety of unique qualities, and it becomes an ideal choice for a diversity of application projects. It is highly useful for manufacturing various products with a host of advantages. Some of the most common advantages of using PP include:

Despite the fact that PP is a great injection molding material, it also has some disadvantages. Here are disadvantages in more detail:

The advocacy organization Environmental Working Group classifies PP as of low to moderate hazard.PP is dope-dyed; no water is used in its dyeing, in contrast with cotton. In 2020 researchers reported that polypropylene infant feeding bottles with contemporary preparation procedures were found to cause microplastics exposure to infants ranging from 14,600 to 4,550,000 particles per capita per day in 48 regions. Microplastics release is higher with warmer liquids and similar with other polypropylene products such as lunchboxes.

Polypropylene is a popular material due to its low cost, ease of use, low density and weight. It can be used for various products of different industries , which include: