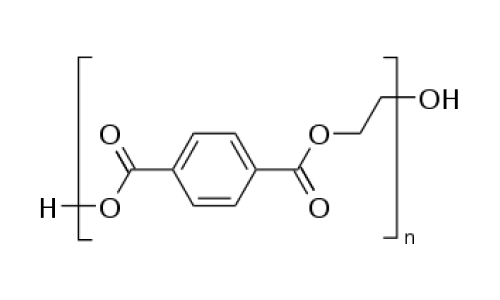

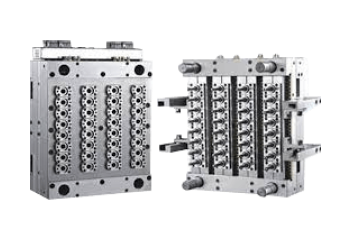

Polyethylene terephthalate (or poly(ethylene terephthalate), PET, PETE, or the obsolete PETP or PET-P), is the most common thermoplastic polymer resin of the polyester family. In its most stable state, PET is a colorless and semi-crystalline resin. It is a thermoplastic material with a well-rounded thermal, mechanical, and chemical properties. It is strong and impact-resistant. As an injection molding solution expert, Echofast offers customers excellent product properties of the PET molded parts with improved efficiency and lower friction. It’s our priority to develop custom molded parts and meet customers' needs.

| Molecular formula | (C10H8O4)n |

| Density amorphous | 1370 kg/m3 |

| Density crystalline | 1455 kg/m3 |

| Young's modulus(E) | 2800–3100 MPa |

| Tensile strength(σt) | 55–75 MPa |

| Elastic limit | 50–150% |

| notch test | 3.6 kJ/m2 |

| Glass temperature | 75 °C |

| melting point | 260 °C |

| Vicat B | 170 °C |

| Thermal conductivity | 0.24 W/(m·K) |

| linear expansion coefficient (α) | 7×10−5/K |

| Specific heat (c) | 1.0 kJ/(kg·K) |

| Water absorption (ASTM) | 0.16 |

| Refractive Index | 1.5750 |

| Drying Index | Drying is essential prior to molding. PETs are very sensitive to hydrolysis. Recommended drying conditions are 120 - 165 C (248 - 329 F) for 4 hours. The moisture content should be less than 0.02%. |

| Melt Temperature | 265 - 280 C (509 - 536 F) for unfilled grades;275 - 290 C (527 - 554 F) for glass reinforced grades |

| Mold Temperature | 80 - 120 C (176 - 248 F); preferred range: 100 - 110 C (212 - 230 F) |

| Material Injection Pressure | 30 -130 MPa |

| Injection Speed | High speeds without causing embrittlement |

With its good chemical resistance and low moisture absorption, PET plastic is well suited for injection molded parts with high demands on dimensional accuracy and surface quality.

PET can reduce weight, improve friction,sustainability and efficiency, and it is widely used in electrical applications, consumer products, and automotive. PET is often used for the following parts: