Nylon 6

Nylon 6/6

Nylon 66

Nylon 6/66

Combs

Cameras

Quick-release buckle

Hand cranks

Spools

Gears

Bearings

Bushings

Slides

Screws

Structural parts (with glass)

Pump parts

Under-hood components

Wear pads

Guide wheels

High-ware parts

General-purpose acrylic

Sign-grade acrylic

Marine-grade acrylic

Crylux

Hesalite

Plexiglas

Acrylite

Lucite

Perspex

Light pipes

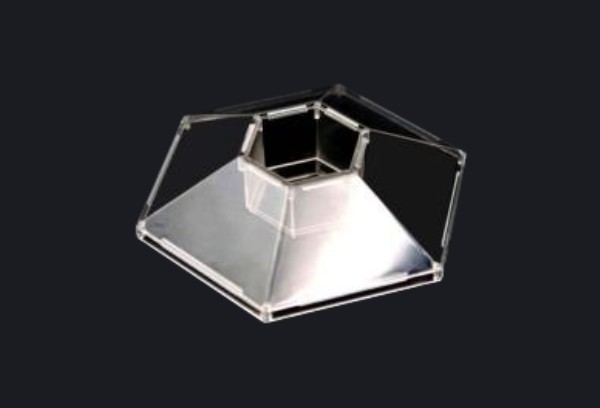

Lenses

Light shades

Optical fibers

Signs & displays

Interior and exterior panels

Bumpers

Fenders

Windows

Appliances

Furniture

Dental equipment

Medical storage devices

Samsung Starex

Toray Toyolac

BASF Terluran

Ineos Lustran

Electronics

Keyboard keys

Phone adaptors

Phone hardware

Protective headgear

Electrical outlet wall plates

Wall socket plastic guards

Automotive parts like wheel covers

Consumer goods

Kitchen appliances

Sports equipment

Industrial fittings

LEGO bricks

Drainpipe systems

SABIC Lexan (flame-resistant versions)

Covestro Makrolon (glass-like transparency)

Lenses

Indoor and outdoor lighting

Safety helmets

Cell phone housings

Equipment housing

Electrical components

Automotive parts

Medical devices

Bulletproof glass

Clear molds for urethane and silicone casting

UHMWPE

ULMWPE or PE-WAX

HMWPE

HDPE

HDXLPE

PEX or XLPE

MDPE

LLDPE

LDPE

VLDPE

CPE

Consumer plastic parts

Containers

Packaging

Plastic bottles

Trash cans

Toys

Housewares

Automotive parts

Corrosion-resistant piping

Plastic lumber

Laboratory equipment

Molding liners for tanks and ponds

Unfilled PEEK

30% glass filled PEEK

30% carbon filled PEEK

Bearing grade PEEK (also known as PTFE PEEK, carbon fiber-reinforced with graphite PEEK, Ketron® HPV, etc.)

Bearings

Gears

Piston/pump components

Cable insulation

Fasteners for electronic devices

Semiconductor manufacturing equipment

Surgical instrumentation

Manifolds

Medical implants

Automobile components

Aerospace components

FDA-compliant food contact equipment

Delrin

Kocetal

Ultraform

Celcon

Ramtal

Duracon

Kepital

Polypenco

Tenac

Hostaform

Gears

Pumps and pump impellers

Fan and blower blades

Automotive switches

Electrical switch components

Fasteners

Parts for knives and firearms

Bearings

Conveyor belts

Pulley wheels

Eyeglass frames

Pure polypropylene( commodity plastic the lowest density)

High crystalline polypropylene (HcPP) (filled with glass fibers for rigidity.)

Semitron® from Mitsubishi Chemical Advanced Materials (popular brand)

Power tool bodies

Hinges

Pipes

Laboratory equipment

Medical pipette tubing

Storage containers

Appliances

Packaging

Pallets

Snap-over lids (e.g., shampoo bottle tops)

Toys

Sporting goods

American Styrenics PolyRenew

BASF Polystyrol

Packaging

Cutlery

Containers

Trays

Toys

Cassette cases

Electronic housing

Glazing

Tool cases

Plastic utensils

Optics

Commercial

Medical

Industrial

Lanxess

Lubrizol

Texin

Ultralast

Footwear

Gaskets

Caster wheels

Sporting goods

Cases or enclosures for electronics and medical device

Protective wire and cable sheaths

|

Moulding Materials

|

Max Temp

|

Chemical resistance

|

Tensile strength

|

Flexural strength

|

Impact strength

|

|

Acrylonitrile Butadiene Styrene (ABS)

|

60 – 93℃

|

Poor to fair

|

6,600 psi

|

270,000 – 380,000 psi

|

3.0 – 7.5 ft-lb/in

|

|

Nylon

|

93 – 177℃

|

Good to excellent

|

6,000 – 24,000 psi

|

390,000 – 1,100,000 psi

|

2 – 8 ft-lb/in

|

|

High density Polyethylene (HDPE)

|

120℃

|

Good to excellent

|

3,200 – 4,500 psi

|

145,000 – 225,000 psi

|

0.4 – 4 ft-lb/in

|

|

Low density Polyethylene (LDPE)

|

65 – 90℃

|

Good to excellent

|

1,200 – 4,000 psi

|

35,000 – 48,000 psi

|

Not breakable ft-lb/ in

|

|

Polycarbonate (PC)

|

288 – 316℃

|

Poor to fail

|

8,500 psi

|

13,500 psi

|

2 – 18 ft-lb/in

|

|

Polyoxymethylene (POM)

|

180 – 230℃

|

Excellent

|

6,000 – 22,000 psi

|

120,000 – 170,000 psi

|

0.8 – 2 ft-lb/in

|

|

Acrylic (PMMA)

|

130℃

|

Excellent

|

2,800 – 10,900 psi

|

13,000 psi

|

0.22 – 1.1 ft-lb/in

|

|

Thermoplastic Polyurethane (TPU)

|

71-121℃

|

Fair to good

|

6,960 – 12,000 psi

|

0.8 – 10.1 ft-lb/in

|

|

|

Polypropylene (PP)

|

65 – 148℃

|

Excellent

|

4,500 – 18,500 psi

|

210,000 – 1,500,000 psi

|

1.4 – 5.5 ft-lb/in

|