Injection Molding Materials for Automotive Parts

Echofast offers various plastic materials to meet the broad needs of automotive applications. It is important to

choose the right plastic. The following is a list of the commonly

utilized materials for automotive injection molding products.

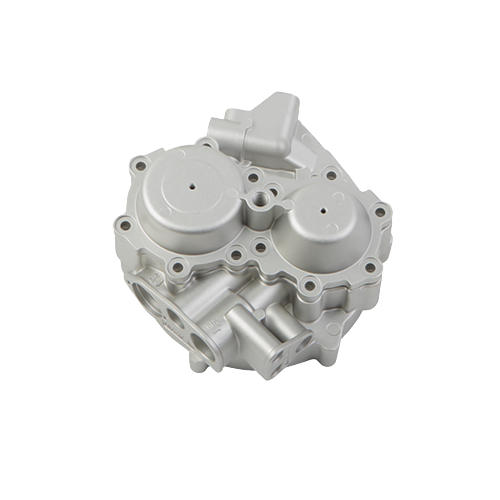

Acrylonitrile butadiene styrene (ABS)

As a durable and fairly weather-resistant plastic, ABS is widely used for automotive applications like

dashboards and covers.

Polyamide (PA)/ Nylon

With good abrasion and chemical resistance, polyamide (PA) or Nylon being wear-resistant in nature may be used

to make items like bushes and bearings.

Polymethyl methacrylate (PMMA) / Acrylic)

Acrylic can be used as a splendid substitute for glass in that it is transparent plastic with high strength,

optical clarity, and stiffness. It can be molded into automotive

components like headlight covers and internal screens.

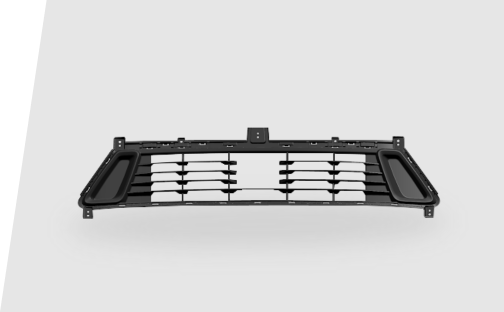

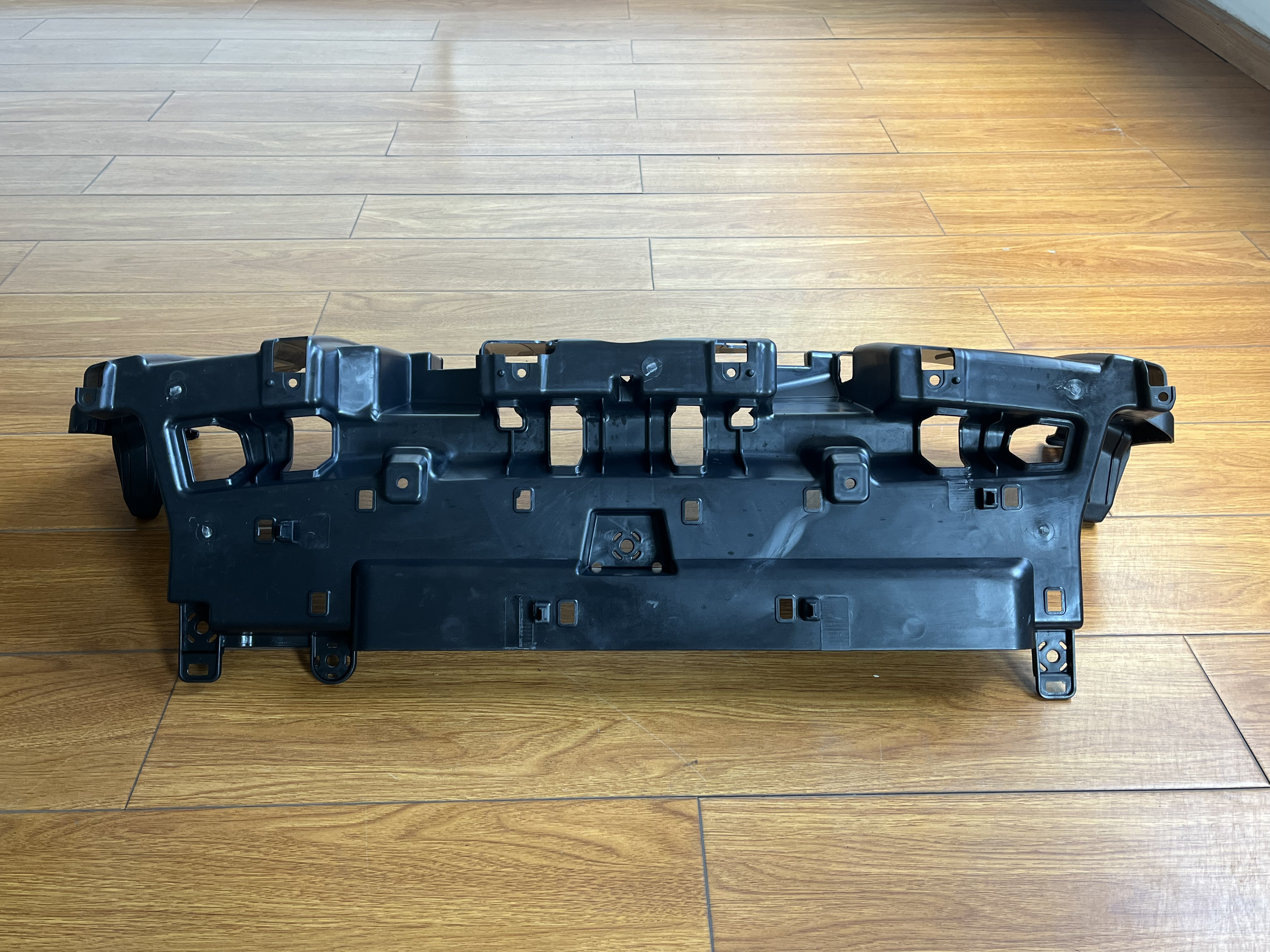

Polypropylene (PP)

Polypropylene (PP) is ideal for some of the more high-intensity automotive parts because of its resistance to

water, chemicals, and UV. It is used in making parts such as

bumpers, cable insulation, and battery cover.

Polyurethane (PU)

PU is frequently used to produce spongy and flexible items like foam seating, which includes car seating. It is

also used for making other auto applications, including seals

and gaskets, insulation panels, and suspension bushings.

Polyvinyl chloride (PVC)

PVC is a popular synthetic plastic polymer, which makes about 16% of the car’s plastic components. It is

flexible and heat resistant, and it is used to make parts that

require good chemical resistance,such as interior panels, dashboards, and cable insulation.

Polyethylene(PE)

Being strong, lightweight, and resistant to impact, polyethylene is helpful when moisture resistance and low

cost are the top priorities.