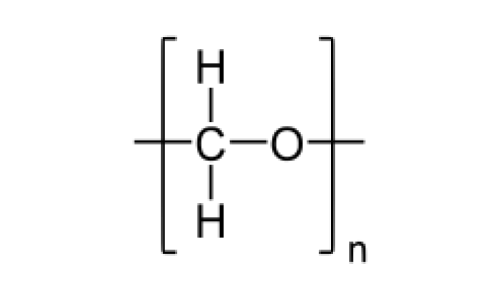

Polyoxymethylene (POM), also known as acetal, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability. POM injection molding refers to the process of creating parts by injecting molten POM (Polyoxymethylene) material into a mold,where it cools and solidifies. Echofast allows for the creation of complex and precise parts with repeatability and an outstanding resistance to creep.

Here are some POM trade names, and you can find related materials properties.

| Delrin® 100 BK602 | Duracon® M90-44 | Celcon® M90 | Kepital® F20-03 | Hostaform ®C9021 | ||

|---|---|---|---|---|---|---|

| Physical | Density (g/cm3) | 1.42 | 1.41 | 1.41 | 1.41 | 1.41 |

| Shrinkage Rate (%) | 1.9–2.2 | 2.1–2.3 | 1.9–2.2 | 2 | 1.8–2 | |

| Rockwell Hardness | 120 R | 80 M | NA | NA | NA | |

| Mechanical | Tensile Strength at Yield (MPa) | 72 | 62 | 66 | 65 | 64 |

| Elongation at Yield (%) | 23 | 35 | 10 | 10 | 9 | |

| Flexural Modulus (GPa) | 2.9 | 2.5 | 2.55 | 2.55 | NA | |

| Flexural Strength (MPa) | NA | 87 | NA | 87 | NA | |

| Injection Molding | Drying Temperature (°C) | 80–100 | NA | 80–100 | 80–100 | 120–140 |

| Drying Time (hrs) | 2–4 | NA | 3 | 3–4 | 3–4 | |

| Melt Temperature (°C) | 215 | 200 | 205 | 180–210 | 190–210 | |

| Mold Temperature (°C) | 80–100 | 80 | 90 | 60–80 | 85 |

Drying

Drying is not usually required for POM, but it is better to store the material in a dry environment.

Melting Point

180 – 230 degrees Celsius (or 356 – 446 degrees Fahrenheit) for homopolymer; 190 – 210 degrees Celsius (or 374 – 410 degrees Fahrenheit) for copolymer.

Mold Temperature

50 – 105 degrees Celsius (or 122 – 221 degrees Fahrenheit); precision molding requires higher mold temperatures, because it can reduce post-molding shrinkage.

Plastic Injection Molding Pressure

70 – 120 MPa

Plastic Injection Molding Speed

Medium to High

1.High strength

As a highly durable and rigid engineering plastic,POM can provide exceptional strength and stiffness for parts. It is an ideal material for applications that require high strength and resistance to wear and tear.

2.Dimensional stability

POM is characterized by dimensional stability, which enables injection molded POM to retain its shape and size. This material is widely used in precision engineering and high-tolerance applications.

3.High heat resistance

With a high heat deflection temperature, POM can withstand high temperatures without deforming or losing its mechanical properties.It has a better long-term thermal resistance.

4.Low friction and wear resistance

POM has a low coefficient of friction, which results in excellent lubricity and wear resistance. Therefore, it is a popular choice for demanding applications that require low friction and wear resistance .

5. Good chemical resistance

POM is resistant to many chemicals,including solvents, fuels and oils. This makes it often used to mold fuel tanks and chemical storage tanks.

6.Cost-effective

POM injection molding is cost-effective, which allows for high-volume production with the low cost. It guarantees consistent quality and minimal waste, and is ideal for mass production.

With good strength and durability, POM is a good resin choice for mechanical components such as: