Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. It can be solid or foamed.It is a light weight material popular for its high impact strength and toughness. Polystyrene (PS) injection molding is a manufacturing process for producing parts by injecting molten Polystyrene (PS) into a mold. Echofast offers custom plastic mold service with expert consultation on each injection mold quote, and we can meet your unique needs while providing a fast and easy manufacturing experience.

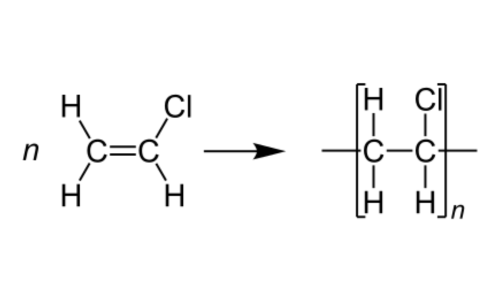

As a thermoplastic polymer, PVC comes in rigid (sometimes abbreviated as RPVC) and flexible forms. Its properties are usually categorized based on these forms.

| Property | Unit of measurement | Rigid PVC | Flexible PVC |

|---|---|---|---|

| Density | g/cm3 | 1.3–1.45 | 1.1–1.35 |

| Thermal conductivity | W/(m·K) | 0.14–0.28 | 0.14–0.17 |

| Yield strength | psi | 4,500–8,700 | 1,450–3,600 |

| MPa | 31–60 | 10.0–24.8 | |

| Young's modulus | psi | 490,000 | —— |

| Gpa | 3.4 | —— | |

| Flexural strength (yield) | psi | 10,500 | —— |

| MPa | 72 | —— | |

| Compression strength | psi | 9,500 | —— |

| MPa | 66 | —— | |

|

Coefficient of thermal expansion (linear) |

mm/(mm °C) | 5×10-5 | —— |

| Vicat B | °C | 65–100 | Not recommended |

| Resistivity | Ω m | 1016 | 1012-1015 |

| Surface resistivity | Ω | 1013-1014 | 1011-1012 |

Typically, PVC boasts the versatile nature and excellent properties include high impact strength, high density, hardness and durability, outstanding tensile strength, and resistance to environmental and chemical degradation.

| Drying |

Not usually necessary as PVC absorbs very little water. |

| Melt Temperature | 160 - 220 C (320 - 428 F) |

| Mold Temperature | 20 - 70 C (68 - 158 F) |

| Material Injection Pressure | Up to 150 MPa |

| Packing Pressure | Up to 100 MPa |

| Injection Speed | Relatively slow, to avoid material degradation |

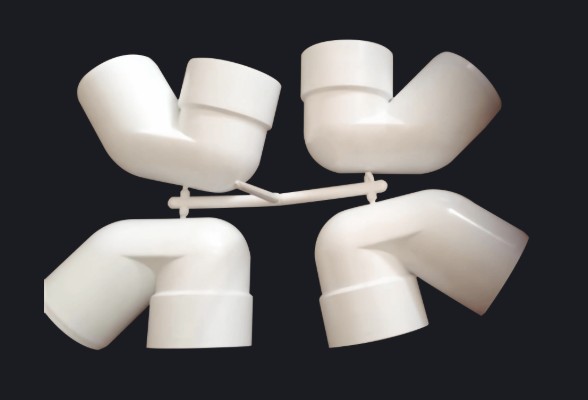

PVC injection molding is a popular process used in a variety of industries. Some common products that use the injection molding process include: