Advantages of Automotive Die Casting

Compared to other traditional metal fabrication methods, automotive

die casting has its own advantages.These advantages are listed and

described below:

- Manufacture of Lightweight Component

- Enhanced Automation and Flexibilit

- Increased Sustainability of Component

- Precise and complex part

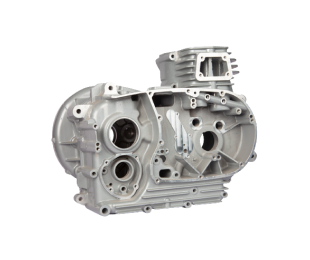

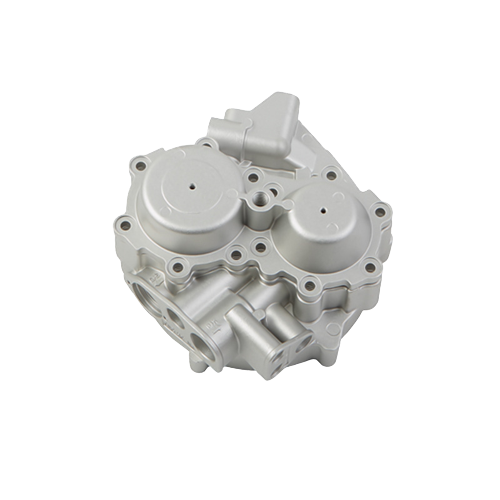

Manufacture of Lightweight Components

Automotive die casting is a cost-efective way to fabricate lightweight

components. The use of lighter metals like zinc, aluminum, copper, and

magnesium faclitates the process.Lightweight components enables the

manufacturers to save money on transportaion and deliver costs .This

results in lower prices for consumers. Lightweight components also can

help consumers to improve their energy efficiency levels. in the

process, less waste is generated, which reduces carbon footprint and

positively impacts global warming issues.

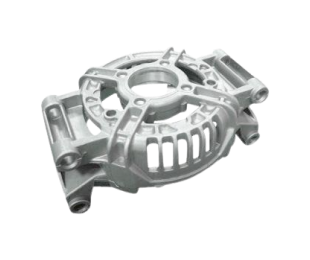

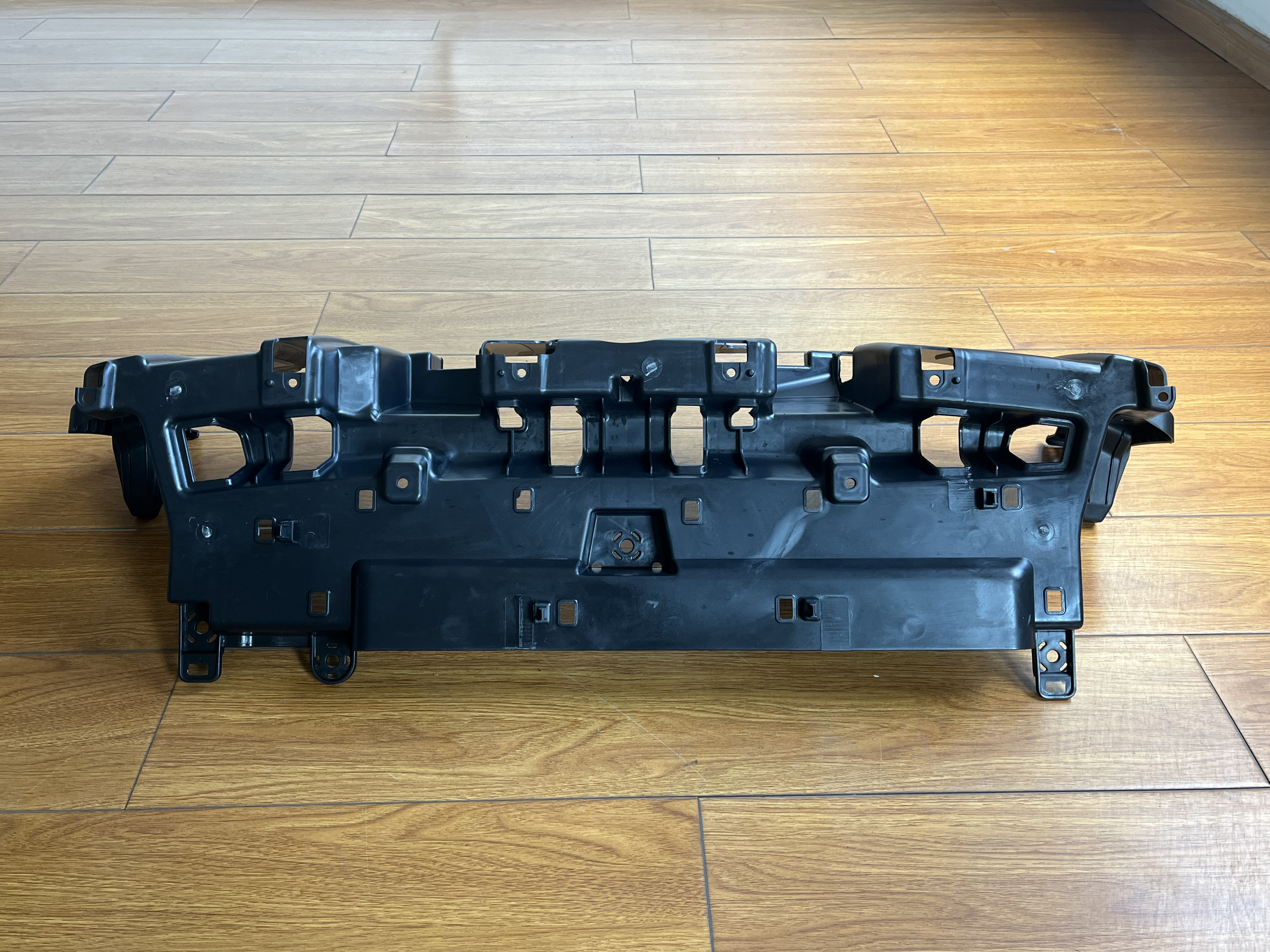

Enhanced Automation and Flexibility

Automotive die casting is an effective method of producing parts in

large quantities. It is suitable for the mass production of vehicles.

It is a highly automated process with great flexibility, and can be

utilized to create various automotive parts in different sizes. By

using the process of automotive die casting, manufacturers can rapidly

produce parts on different vehicles such as wheels, vehicle chassis,

paneling, and suspension components.

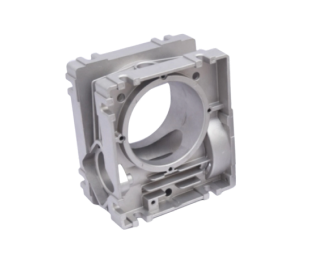

Increased Sustainability of Components

Automotive die casting allows for increased sustainability of

components because of the fabricaton of eco-friendly and sustainable

components .Metals that are commonly used in automotive die casting

are easily recyclable, including aluminum, zinc and magnesium.

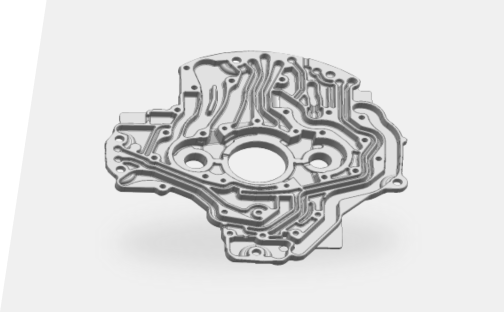

Precise and complex Parts

Complex parts with high dimensional accuracy and durability can be

fabricated with the process of automotive die casting.Dimensional

accuracy in harsh conditions can be ensured due to the low thermal

expansion coefficients from metals, which are commonly used in die

casting.