between the two manufacturing processes. This article will compare injection molding and blow molding from different aspects to help

you accurately decide on the right process.

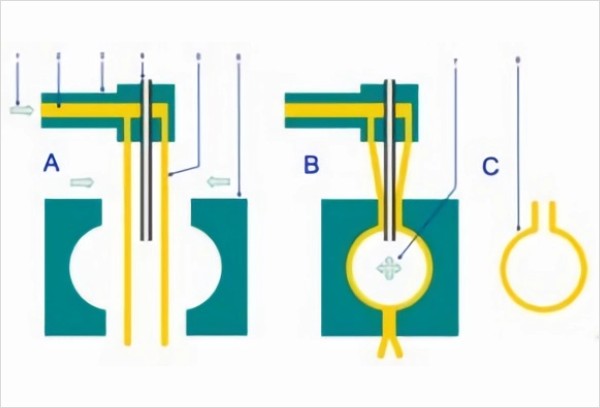

Blow molding is used in a wide range of industries such as automotive, consumer products, medical parts, pharmaceuticals, etc. It is commonly used to manufacture uniform and thin-walled hollow parts such as bottles, water tanks and tubs.

Both blow molding and injection molding are compatible with a variety of materials, especially most thermoplastics. Some materials are widely used for blow molding applications, including Acrylonitrile Butadiene Styrene (ABS), High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), and Polypropylene (PP). Most polymers may be used in injection molding, including all thermoplastics, some thermosets, and some elastomers. What’s more, metal powder bound in a polymer matrix can be injection molded.

Blow molding is applicable for hollow parts while injection molding is well suited to solid parts. The former is commonly used to produce thin-walled hollow parts with flexible or structural properties like custom plastic bottles and containers for consumer products. The latter is used to create parts with a rigid wall, such as some automotive parts , furniture , medical devices and many other consumer products.

Blow molding is less expensive than injection molding because of the cheaper tooling and shorter operation. In addition, it has lower energy requirements when compared with injection molding.

Blow molding and injection molding are commonly used in various types of industries for their efficiency. This article makes a detailed comparison between blow molding and injection molding, through which you can also learn about their specific advantages and disadvantages. Echofast offers high-quality plastic parts by making use of custom injection molding services.