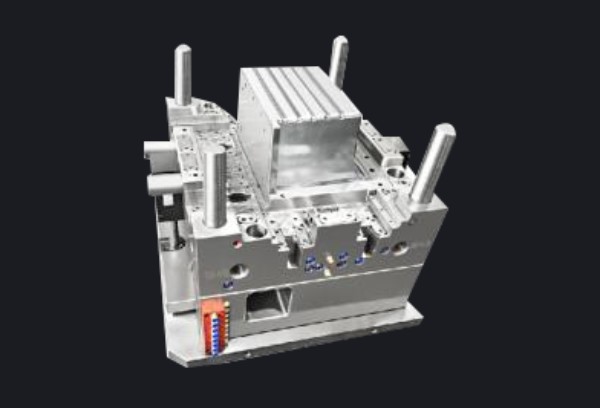

What Is Injection Molding?

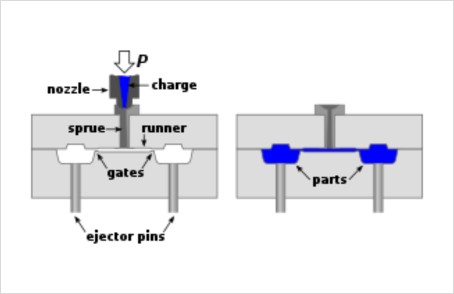

Injection molding is a manufacturing process used to create parts by

injecting molten material into a mold tool, then ejecting the

solidified part with consistent quality. This process can amortize

costs as one orders higher quantities of parts. High production

volumes of complex parts can be achieved with injection molding.

Therefore,the process is well suited to high-volume production of

products with complicated shapes.