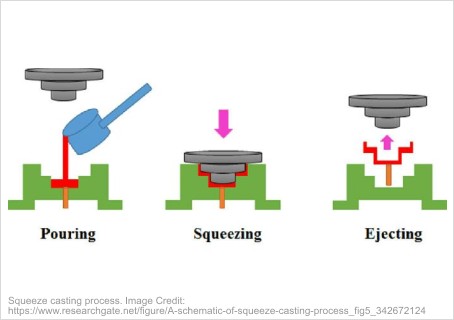

What Is Squeeze Casting?

Squeeze casting, also known as liquid metal forging, is a

manufacturing process that combines casting and forging. It starts by

pouring the molten metal into a heated die. Then, the metal begins to

solidify, and the upper die is closed. With the pressure applied, the

casting cavities are completely filled with metal, which guarantees

accurate shape, minimal shrinkage and remarkable mechanical

properties. The process can be used to cast various metals. Aluminum

and magnesium alloys are most commonly used for the procedure.