+86 13989613556

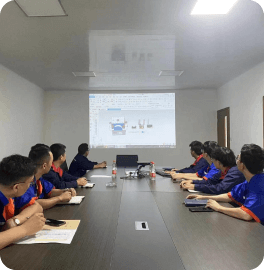

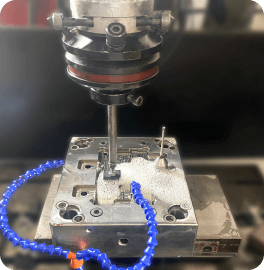

With the certification of ISO 9001:2015, Echofast offers custom die casting services by utilizing the latest die casting machines and technology. Both a detailed DFM report and a mold flow analysis are available before mass production. Our team also operates rigorous quality inspections throughout the process to facilitate the production of high-quality parts .

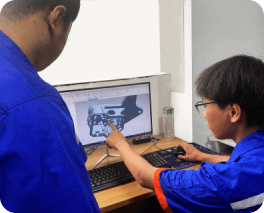

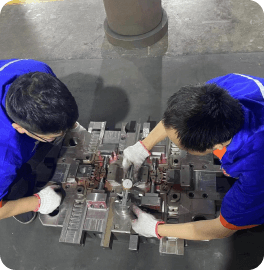

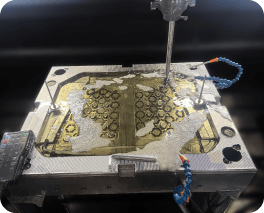

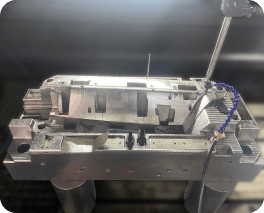

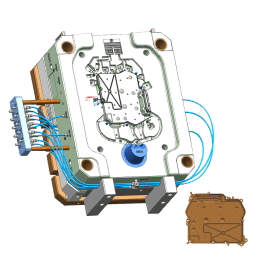

We have mold design and manufacturing, die casting precision machining core technology, as well as the industry's advanced testing equipment.Die casting mold design is a technique for mass-producing metal products and components, which will contribute to the overall success of the process.

Considerations for Die Casting Mold Design:

To help you find your ideal die casting mold, we offer you the catalogue of die casting mold

You can download it whenever you need.

DownloadGood Quality

Globally Competitive Pricing

We are located in Huangyan Mold Processing Cluster in Taizhou , Zhejiang province ,China,

which is the largest mold processing cluster in the world. Professional division of labor and

abundant technical engineer resources are available for better control in our company.

We are aimed to maintain a sustainable cost advantage for customers with custom die casting molds.

Please contact us now! Get a professional custom die casting mold

quote within 24 hours.We provide expert engineering reviews for you.Dozens of materials

and finishes are available.We can offer you a professional quotation list.

Catalogue

Catalogue