What is Investment Casting ?

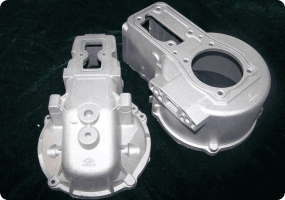

Investment casting, also known as lost-wax casting, is a manufacturing

process used to manufacture complex parts with high precision by

using expendable patterns made of wax-like materials. The process is

valued for its ability to produce components with tight tolerances,

accuracy, exceptional surface qualities, repeatability, versatility

and integrity in a variety of metals and high-performance alloys. It

is ideal for the production of precision castings with thin walls and

fine surface finishes, which can reduce the need for secondary machine

processes. The article will discuss the process of die casting in

detail, and go over its materials, advantages, disadvantages, and

applications.