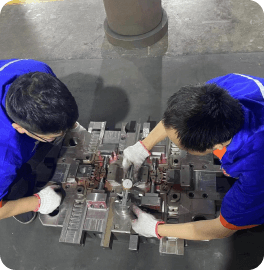

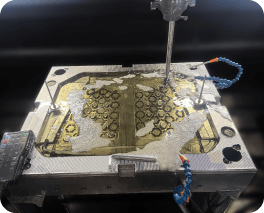

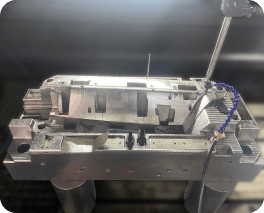

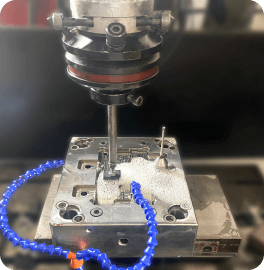

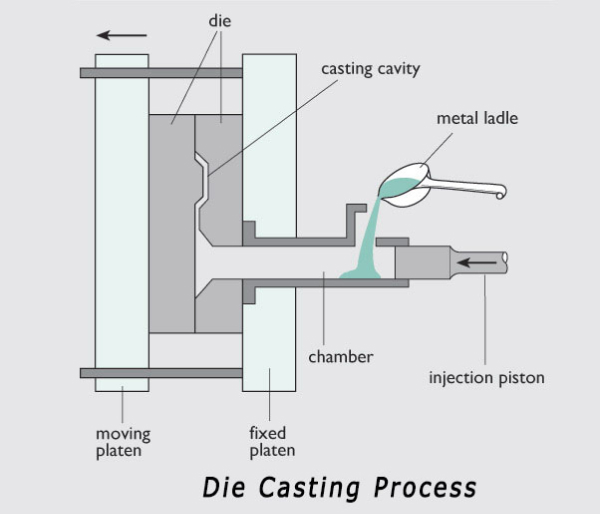

Zinc is one of the most versatile and commonly used die casting metals for its superior strength and durability.Die casting is a process that injects the molten metal into the die casting mold under pressure to create complex parts out of metal. Zinc die casting is the process of forcing molten zinc alloys into a mold with high pressure in order to form a required shape.With its excellent properties, zinc die casting has become one of the most efficient and versatile high-production methods in production.

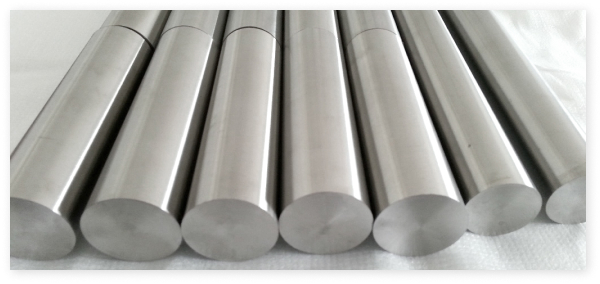

ZAMAK alloys (the conventional):

Alloy 3, Alloy 5, and Alloy 7.

ZA alloys ( with higher amounts of aluminum) :

ZA-8, ZA-12 and ZA-27.

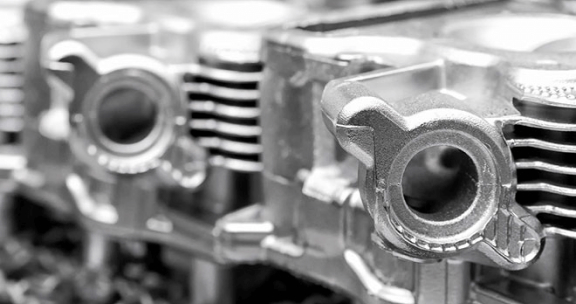

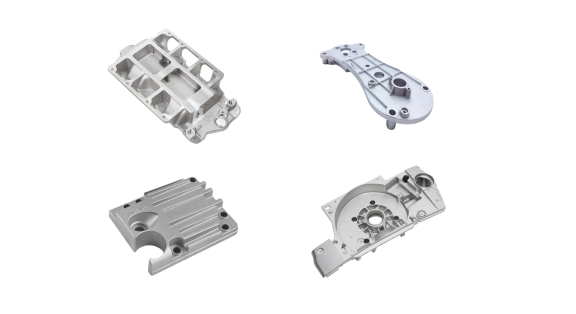

Zinc die casting is highly popular in a host of industries, especially in the automotive industry.Some examples of its applications in different industries are:

Automotive Industry

Electronics

Plumbing Components

Home appliances