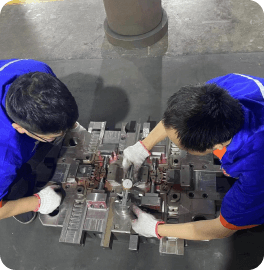

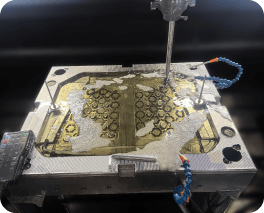

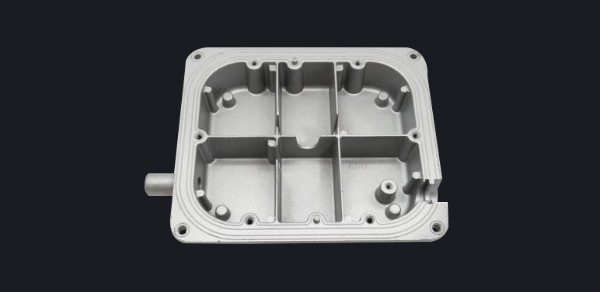

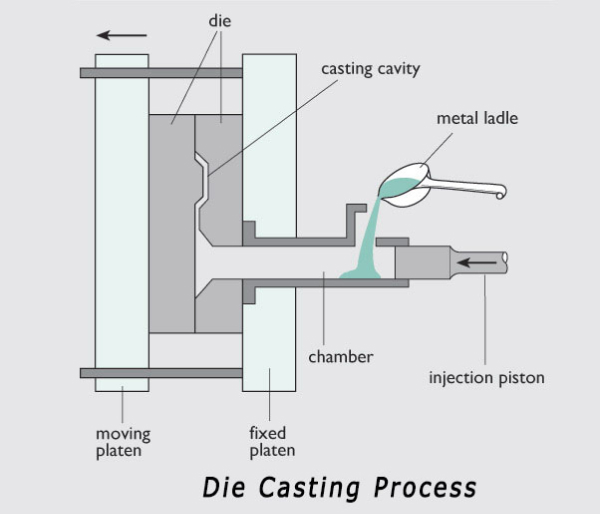

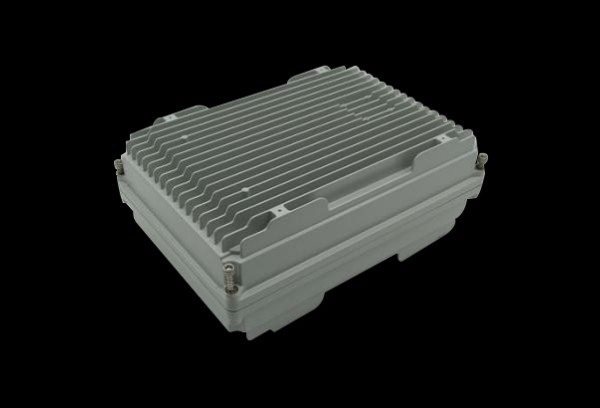

With good strength, corrosion resistance, and heat dissipating properties, aluminum is one of the most common options for cold chamber die casting. Aluminum die casting is the process of introducing molten aluminum into a die cavity,which takes the shape of the part and hardens into place before removal. Generally,the resulting aluminum products are precisely formed with a smooth surface and often require minimal or no machining processes.In another words, aluminum die casting allows for the creation of complex,tight-tolerance aluminum parts in a repeatable manner at very high production volumes.

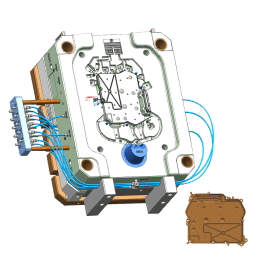

Designing is one of the most crucial steps in successfully and efficiently manufacturing die-cast products. A few considerations should be taken into when designing a product to be made using aluminum die casting.

There are a few aluminum alloys commonly used in die casting. Some of them are:

| Alloy | Corrosion resistance |

Resistance to hot cracking |

Anodizing | Machinability | Common applications |

|---|---|---|---|---|---|

| A380 | Fair | Very good | Good | Good | Workbench vises and other hand tools,gear cases, lawnmower housings |

| A360 | Excellent | Excellent | Good | Good | Instrument cases, irrigation system parts,outboard motor parts,hinges |

| 383 | Good | Excellent | Good | Very good | Engine brackets,cylinder head covers,appliances,furniture, power tools |

| A413 | Excellent | Excellent | Good | Fair | Outboard motor pistons,dental equipment,street lamp housings |

| B390 | Fair | Good | Fair | Fair | Pistons,blocks,manifolds,and cylinder heads for internal combustion engines,brake cylinders |

| 518 | Excellent | Poor | Excellent | Excellent | Architectural castings,conveyor parts,marine and aircraft hardware fittings |

For example, alloy A380 is the perfect jack-of-all-trades, offering a good combination of casting and product properties, and is the most commonly specified alloy for casting a wide variety of products.

A360 offers excellent corrosion resistance, pressure tightness, and very good fluidity when molten.

Aluminum is a kind of non-ferrous die casting alloy with its own mechanical properties.It can have significant advantages over other alloys. Not only can aluminum alloys withstand high operating temperatures, but they are also fully recyclable.Aluminum alloy characteristics include:

Aluminum die casting alloys are not only lightweight, but also possess high dimensional stability, which works well for complex part geometries. Aluminum die casting is generally used in a wide variety of applications, including: